Not all waste streams are the same, and some can be more challenging to compact to target densities than others. By taking in a consistent stream of municipal solid waste (MSW), some operators can alleviate these challenges; however, it is not always possible.

Given that MSW is relatively uniform, compacting the material to target densities and meeting airspace management goals can be less of an issue. However, a waste stream consisting of nonuniform material, such as construction and demolition (C&D) debris, furniture and organic material, can make reaching target densities much more difficult.

For Jennifer Richardson, solid waste and sustainability division director for the Mesa County Landfill in Grand Junction, Colorado, inconsistencies within incoming loads were a challenge.

“Our trash is not uniform MSW,” explains Richardson. In addition to MSW, she says the landfill also accepts C&D, loose material such as furniture, sludge, tree stumps and dead animals.

To efficiently compact this irregular waste stream, the landfill requires a combination of features in a landfill compactor. Weight, wheel design and center-point oscillation, among other items, influence the machine’s ability to achieve target densities. Weight alone cannot deliver the high capacities without a wheel configuration designed to shred and knead material and a flexible oscillation joint to keep the compactor’s wheels in constant contact with the waste.

Better compaction

The Mesa County Landfill currently operates on a 127-acre, constantly evolving footprint. The operation is open 300 days annually and 58 hours per week. On average, it receives roughly 170,000 tons of mixed waste every year, so an efficient and reliable compactor is crucial for its operations. To make the operations more efficient, the landfill started searching for a new landfill compactor to replace its existing one.

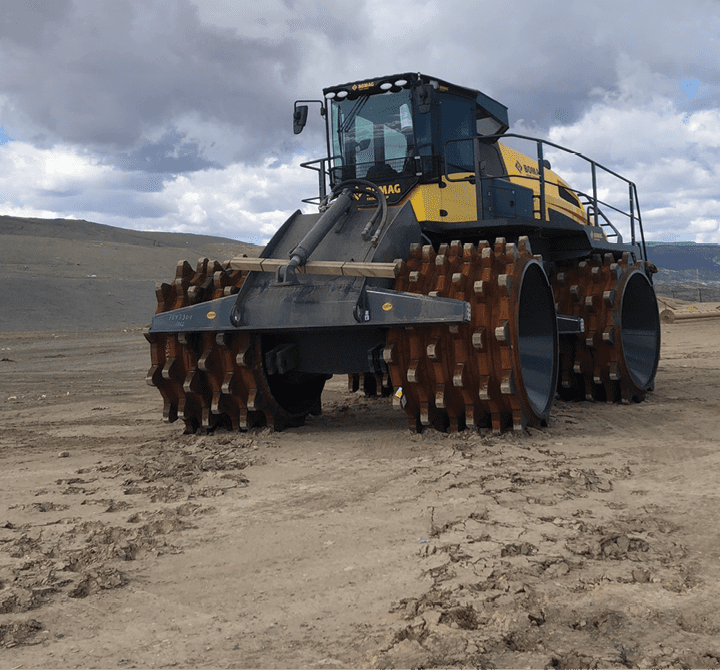

Last year, the landfill took possession of the 125,000-pound BC 1173 RB-5 landfill compactor from Germany-based Bomag GmbH, a Fayat Group company. According to Richardson, one of the first differences workers noticed was its wheel design.

“There are more touch points on these wheels, which we believe gives better compaction,” she says. “The previous compactor used at the landfill had big spaces between the teeth.”

Each of the 55.1-inch-wide front and rear compaction wheels consists of multiple rows of polygonal rings with a total of 72 compaction teeth. Tooth design provides optimum crushing, kneading and compaction at depth, while the polygonal rings provide additional lateral forces to increase compaction performance, Bomag says. In addition, the rear wheels are at an offset to the front to completely close the gaps left by the front wheels.

Because only clean wheels can provide deep material tooth penetration for high compaction performance, the wheel design also includes scraper bars positioned between the rows of teeth. Wire cutters between the wheels and frame prevent wire and rope from wrapping around the wheels, allowing for reduced cleaning and protecting the wheel motors from damage.

The machine’s center articulation joint allows the wheels to track, even in turns, and offers 40 degrees of left/right steering to help with maneuverability. The center joint’s 15 degrees of up/down oscillation help keep the wheels in contact with the material, improving traction and compaction. The oscillation also benefits the operator. “The Bomag is a smoother ride,” Richardson says.

Before switching to the new compactor, Mesa County’s previous machine was making numerous passes over the waste to achieve compaction but with worse results than what it is getting now. The BC 1173 RB-5 delivers target densities in only three compaction passes.

“We are getting compaction rates in the neighborhood of 1,400 pounds per cubic yard,” Richardson says. “This is an improvement over our previous machine by 100 pounds per cubic yard.”

Fewer passes for better compaction also mean the landfill is saving fuel, lowering costs and improving sustainability.

Protecting the investment

Committing to a dedicated piece of heavy machinery with high use rates in a tough operating environment isn’t always an easy decision. However, it’s one decision Mesa County made that is improving landfill operations. Received at the site in May 2021, the BC 1173 RB-5 has been running ever since. With the landfill operating 58 hours per week, the machine logs nearly 3,000 hours each year.

Richardson says the new landfill compactor’s design helps to simplify maintenance. Minimizing daily inspection time, all visual inspection is completed from one side of the machine. A standard lubrication system automatically applies grease to virtually all machine mechanical bearing points with a 500-operating-hour supply.

Service platforms on both sides of the compactor offer quick access to maintenance areas, plus its one-piece engine hood opens wide at the touch of a button to provide unimpeded access to the engine and components. To prevent engine overheating, the compactor’s automatic reversible cooling fan helps to keep the cooling system clear of debris.

Richardson also is working closely with Bomag dealer Power Equipment Co. (PECO), which has a nearby office in Grand Junction, to ensure the investment is well-maintained. “We bought a service package along with the machine, and it gets serviced by PECO every 500 hours,” she says.

Both the Mesa County Landfill and PECO keep tabs on the BC 1173 RB-5’s operation using Bomag Telematic. The system provides critical machine operating information, including fuel usage, to track fuel costs and documentation of all maintenance performed on the compactor to facilitate planning.

With compaction of the loose material and irregular waste stream received by the landfill being of utmost importance, the operation’s choice to switch to the new compactor is paying dividends through increased compaction efficiencies, long-term fuel savings and simplified maintenance and service. The compactor’s ability to consistently deliver an additional 100 pounds per cubic yard of compacting material is helping the Mesa County Landfill optimize airspace management and extend the life of the landfill.

Explore the April 2022 Issue

Check out more from this issue and find your next story to read.

Latest from Waste Today

- US Composting Council grant will fund data collection

- Enviri releases annual ESG report

- Waste Connections enjoys income, revenue boosts

- Machinex recognized as Recycling Equipment Innovator of the year

- WM announces solid Q2 growth

- Reworld partners with Genpact

- Waste Pro earns favorable financing rating

- Amberjack announces exit from investment in Best Trash