Reduction In Motion founder Bill Griffith says waste follows the path of least resistance, like water. In a health care facility where, after a procedure, a practitioner could be holding a tray with five items that need to go into five different disposal containers, waste management demands a holistic approach to ensure everything ends up where it’s supposed to be.

“Waste is something that is often out of sight, out of mind—until it’s not,” says Zach Hetrick, director of new business development for Reduction In Motion, a Fallston, Maryland-based sustainability consulting firm that helps companies reduce waste, increase recycling awareness and facilitate zero-waste projects. “Health care facilities can’t treat it like it’s out of sight, out of mind. These are highly regulated, highly impactful streams if they’re not managed properly.”

Health care facilities tend to generate a tremendous amount of waste, Hetrick says, and properly managing that waste not only boosts a facility’s bottom line but also provides a multitude of benefits to the company, from improving staff safety to improving impacts on the community environment to, ultimately, providing better patient care.

Combatting overclassification

Reduction In Motion got its start in 2002, taking on the role of on-site waste stream manager for a number of health care facilities in the mid-Atlantic region.

At the time, Hetrick says, the focus was on reducing regulated medical waste, particularly “red bag waste,” a type of biohazard that can be infectious, including blood-soaked items, personal protective equipment and used specimen cups.

Griffith has a background in waste and had been working with haulers on treatment technology for regulated medical waste. Through that experience, he learned that health care facilities often were failing to properly separate waste, leading to overclassifying too much waste.

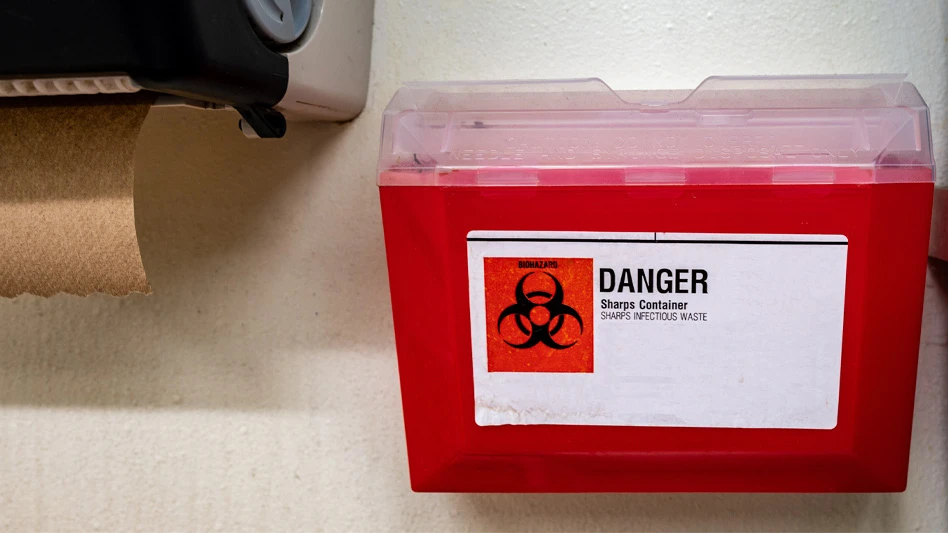

Overclassification can become a problem when general trash such as gloves, paper waste or packaging ends up in containers meant for regulated medical waste streams, such as red bags, sharps containers and pharmaceutical bins, which come with a hefty disposal fee.

“We were working with facilities that had upwards of 75 percent of all of their waste going out in a red bag,” Hetrick says of the company’s initial customers. “It was resulting in excessive cost for them as well as impact on the environment.”

That same early 2000s time period saw the rise of single-use materials in health care facilities—resulting in a rise in the excessive volume of waste—as well as increasing regulation around on-site waste incineration.

“Everyone was fearful and was treating all waste streams as regulated medical waste at many facilities,” Hetrick says. “The opportunity arose to help health care facilities better separate their waste, and that’s how [Reduction In Motion] got started.”

Comprehensive approach

Taking the guesswork out of waste management through efficient infrastructure and communication can make a huge difference to a hospital’s bottom line. Reduction In Motion takes a hands-on approach to waste management, helping facilities go through policies, evaluate waste hauling contracts, implement plans, educate staff and continuously monitor and track progress toward waste diversion goals.

The company’s process generally starts with an audit of the waste management program, an assessment that looks at not just the composition of waste but also the points of generation, containers, signage, separation infrastructure, transportation and material flow, training, education and hauler contracts.

To help combat overclassification, the Reduction In Motion team focuses on communication and messaging around which specific items need to go into which specific containers and then ensuring disposal infrastructure, communication and signage are aligned.

Next steps involve creating a plan that typically includes on-site training to educate nurses, clinicians and pathologists on the different types of waste and how to separate them. A typical client facility will have about 12 primary waste streams and up to 20 total different waste streams that need to be identified and addressed, Hetrick says, which requires multiple stakeholders be involved in the discussions.

“It’s not just environmental services,” Hetrick says of those stakeholders. “We’re talking upwards of 10-15 different primary points of contact to be involved in this planning so you don’t get one message about how to dispose of chemo waste and this other message on how to dispose of pharmaceuticals and it’s all coming in from different directions. It’s one cohesive message around waste and pulling everything together at once to make sure it’s accurate, up to date and effective.”

As a vendor-neutral consultant, Reduction In Motion doesn’t have any relationships with specific haulers and does not advocate for clients to purchase certain pieces of technology, Hetrick says.

“We’re really an extension of our client’s team and help them best characterize their waste, understand where they’re at and help them take the next practical steps,” Hetrick says. “Because managing waste requires a system, and this isn’t a bunch of quick fixes or silver bullet-type initiatives that have instant impact. Waste requires constant management and thought and engagement of your staff to maintain the results you want.”

Fostering better compliance

Typically, clients will come to Reduction In Motion with one of two goals: an ambition to be more sustainable or a need to be more compliant.

Medical waste compliance has been in the headlines recently in California, where the state attorney general hit Kaiser Foundation Hospitals with a $49 million fine for improper disposal of hazardous and medical waste and protected patient information at Kaiser Foundation Hospitals facilities statewide.

In that case, according to the California Department of Justice, district attorney inspections discovered that regulated medical waste, hazardous waste and confidential inpatient information, such as patient wristbands, were being disposed of in general waste containers.

For facilities that have struggled with compliance, Reduction In Motion can help strengthen a waste management program and increase awareness and education around proper disposal.

“All facilities in all states should be really honing in on how they’re communicating around those three highly specialized waste streams and then showing that their programs are tight enough that these items aren’t going out in the general landfill trash,” Hetrick says.

Beyond health care

In addition to medical facilities, Reduction In Motion now works with higher-education institutions, manufacturing facilities and stadiums across the country.

Many of the waste management lessons learned from health care can be applicable in other settings, Hetrick says. In any type of facility, the team takes a comprehensive approach rather than focusing on any one waste stream or initiative.

Additionally, while very few facilities will have as many waste streams as a hospital, every facility needs to take into consideration all of its various waste streams.

“You need to understand how the whole system works, not just approach any one waste stream and not trying to go into it with any one department,” Hetrick says. “It’s really about getting the stakeholders together and approaching your waste in a holistic way.”

Finding commonalities

While every health care facility is different—some essentially are small cities, while others are specialized around one service—when it comes to waste management, the essentials remain the same: making sure each facility has the right containers and a good communication strategy.

“So, that’s the labels, that’s the signs, so people know how to separate at the point of generation,” Hetrick says. “You’re making sure housekeeping has a good, compliant process for managing that waste, and you’re making sure that the equipment is appropriate and custom for that facility.”

From there, success ultimately relies on effective follow-through.

“You’ve got to keep up with that education, keep that communication constant and not let your program slip,” Hetrick says. “It can be very easy to backslide and go right back to where you started after many years of work.”

Explore the May/June 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Waste Today

- WM reports revenue, earnings growth in Q4 and full-year 2025

- Reclamation Technologies USA acquired by investment fund

- Stadler equips Spanish MRF

- Amlon adds Mastermelt facility to its portfolio

- US Composting Council releases draft bank loan kit

- Vecoplan appoints CFO

- Recovered paper traders report lukewarm market

- Maverick Environmental Equipment opens Detroit area location