“Telematics impacts every business,” states Chris Oliver, chief marketing officer for Zonar. Integrated communications generate such information as fuel consumption, number of stops per route, and the amount of time it takes to complete a route. That information helps fleet managers reduce fuel costs and increase productivity through better routing.Oliver contends that telematics systems also improve safety as well as efficiency through visibility. Zonar’s onboard telematics system for fleet management is unique, he says, because it’s the only verified visual electronic vehicle inspection system available, providing real-time diagnostics and GPS tracking.

The easy-to-install EVIR system automates many tasks typically performed manually. Small RFID are tags placed around the vehicle, Oliver explains. An RFID reader tells the driver what to check. When he does, a list of conditions pops up. “There are a dozen zones, each with a list of components. Each of those has a list of conditions to check.”

Data is then transmitted in real time, allowing the information to be disseminated immediately. “In most cases, it reduces labor costs,” Oliver contends. “You also know when you started an inspection and how long you spent.” That can be important in a union shop, where contracts allocate a specific amount of time for inspections. Oliver says 15 minutes is average, adding that the 150,000 vehicles using Zonar’s patented system average 12 minutes. That increases uptime.

It’s attracting attention because the importance of pre- and post-trip inspections is recognized by every fleet manager, Oliver continues. Inspections have always been important, but now that more roadside inspections are occurring due to Compliance Safety Accountability, a Federal Motor Carrier Safety Administration initiative to improve large trucking safety, safety ratings are in jeopardy. “This forces operators to do inspections, which increases the safety of the vehicle. Inspections happen, safety improves [and] the data goes to the right person.”

But this “inspection solution” is only second on the list of requests from fleet managers, Oliver says, and remote diagnostics slots in behind that. The No.1 request from customers is for basic GPS info: where, when, speed, idle. For customers who want to track their containers, Zonar’s Ztrack, a battery-powered GPS locator, is used with rolloff containers. “EVIR provides accurate can counts with a time/date/location stamp. You get real-time information on pickup, which benefits customer service. Rehrig Pacific puts RFID tags in the totes so you can even read the cans at the neighbors.'”

EVIR produces a lot of data-data “like there hasn’t been in the past,” Oliver argues. The challenge is to turn data into information that can be effectively used by the customer. “Our question is how to mine data for customers. We are driven by customer innovation; we’re not the experts in waste collection. We listen to the customer and use their experience to help make the most of the data.” However, at this time, he says the technology is ahead of management.

Some customers know how to use the data to their benefit. Oliver mentions the city of Sacramento, CA, which achieved a 20% fuel consumption reduction by using EVIR to monitor idle time and for route optimization and speed control.

Similarly, the Environmental Services Bureau in Long Beach, CA, which serves 125,000 residential and commercial accounts annually, uses Zonar’s electronic fleet management system, including EVIR, V2J HD-GPS and Ground Traffic Control to monitor its waste fleet and its street sweeping fleet, which cleans an average of 170,000 curb miles and 3,000 alley miles each year. Environmental Services Bureau Manager James Kuhl chose EVIR because it’s the only system able to manage two operational requirements: vehicle tracking and inspections.

Since incorporating the system, the bureau reports decreased fuel consumption and emissions due to its ability to efficiently manage vehicle idle times and reduce miles driven through advantageous rerouting, an unexpected benefit. This contributes to their efforts to reduce their fleet’s carbon footprint.

Biannual inspections by the California Highway Patrol are now straightforward, they report, thanks to automatic recordkeeping. And because service time, location, vehicle speed, and operator are all documented, the bureau has been able to verify that operations comply with policy requirements.

Some of the drivers have a “Big Brother fear,” Oliver admits. But, “on the flip side, it shows which drivers are doing a good job. It’s an “˜atta boy’ opportunity.” Rewarding drivers for fuel economy, safety, speed and/or the number of cans picked up is in its infancy, but illustrates the direction the industry could be taking.

In addition to measuring route performance and driver performance, Oliver points out that telematics could drive billing if a company charges per pickup. Most importantly, he believes, telematics enhance safety and efficiency and promote compliance.

Founded in 2001, Zonar technology is used on 300,000 vehicles. “We were the first to market with the 36 cellular modem,” Oliver says, adding that AT&T is sunsetting the 26 network in 2017.

Validating Telematics

Public and private refuse fleet managers are faced with high fuel costs, aging equipment, and shrinking budgets. Within those parameters, they must continue to maintain service levels while increasing productivity and addressing environmental concerns. Doug Yglesias, aftermarket business development manager for Parker Hannifin’s Hybrid Drives Systems Division, believes that telematics can help fleet managers validate the purchase of advanced equipment technology that can assist in those goals. “Telematics provides [fleets] their own information rather than relying on [an] OEM’s scenario of how the product will perform.”

Hydraulic hybrids are an example of advanced equipment that can benefit a fleet through fuel savings, extended brake life, improved working conditions, and increased productivity. Yglesias says that refuse vehicles have documented an average of 43% savings in fuel consumption annually and a 50% reduction of carbon-dioxide emissions. Because the hydraulic hybrid’s regenerative braking system limits traditional friction braking, brake replacement cycles are reduced from three to four change intervals per year to twice during the life of the truck, saving tens of thousands of dollars.

In order to determine how equipment benefits a fleet, a benchmark and route history must be established. Then a fleet manager can evaluate the routes, maximize each driver’s time and evaluate the effects of fuels on fuel consumption. Real-time information alerts managers to such truck issues as engine trouble or brake problems so they can be addressed before the vehicle fails in the field.

A baseline should include such data as gallons of fuel used per day, price per gallon of fuel, number of hours of operation, miles driven on a route per day, number of cans picked up per day on a route, per-hour operating cost, how often the brakes are changed out on a vehicle, and the cost of the brake changes.

Once a fleet manager has established a baseline and defined goals, data can be reviewed to assess the success of the fleet’s procedures.

“Parker is continuously looking for ways to help [fleets] achieve optimum performance,” says Yglesias. “In the case of hydraulic hybrid transmissions, we are looking at capturing more information.” Parker offers subscription-based, real-time, onboard diagnostics and data collection to provide such notifications as fuel savings and downed trucks. This option will help identify items that increase productivity and reduce waste.

Getting Onboard With Diagnostics

“Onboard diagnostics are required in 2013,” says Glenn Pochocki, national sales manager for Crane Carrier, “and onboard diagnostics, phase two, is coming next year.” It’s mostly an updated version of the 2010 exhaust emissions system that involves resizing, new positions of the diesel exhaust fluid, more seals, specialized clamps, and more insulation to retain exhaust heat for self-cleaning in order to reduce greenhouse gas.

The US Environmental Protection Agency and the Department of Transportation enacted new greenhouse gas and low-efficiency standards that will take effect in 2014 and 2017. These will result in fewer carbon-dioxide emissions. The EPA will also require onboard diagnostics in vehicles weighing over 14,000 pounds, with the intention of lowering nitrogen oxides and particulate matter. To comply with the new standards, aftertreatment devices such as diesel particulate filters and nitrogen-oxide-reducing catalysts will be monitored.

Cummins has incorporated OBD since 1997, according to Christy Nycz, onsite highway communications manager. It continuously monitors the exhaust system, providing alerts via a malfunction indicator lamp on the dashboard. Cummins service tools will also support the latest standard-heavy-duty OBD, which will monitor exhaust emissions.

Heavy-duty OBD has a new feature: a pending fault. It triggers an alert when a problem is suspected but the vehicle hasn’t run enough to confirm it. To fully confirm that a repair has been effected, the technician must test-drive it. At that time, it will be dismissed. A permanent fault stays in the system to prevent cheating on emissions tests. Proof of the repair will be required in order to pass.

An added function is making diagnostics easy to understand. “Allison has developed a fifth generation of electronic controls that are easier to read,” Pochocki says. “The fourth generation had coded messages that were difficult to decipher.”

Simplicity is the name of the game in monitoring devices. Cummins consolidated everything into one module that measures the quality of diesel exhaust fluid and limits horsepower or operating speed as desired. The oil can be monitored, as well as life expectancy of the transmission filter and fluid.

Furthermore, shutdown characteristics can be programmed on engine monitors. “If the oil pressure is low or the coolant temperature is high, the engine will shut down,” Pochocki explains. It can be restarted for a short period in order to move to the side of the road.

By making complex circuits simpler to manage, there are more opportunities for simple diagnostics, Pochocki postulates. “A bad ground, loose connection or a break in the wire were difficult to detect. It was a game of hide-and-seek. Now, you just plug in to see the issue.”

More technology will be borrowed from the OTR industry, he believes. “Stability control is common in on-the-road trucking now. It’s coming a few years down the road for the refuse industry-for fixed trucks that see some speed.”

Under Pressure

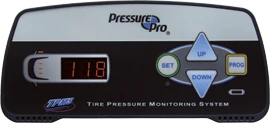

Other monitoring devices also straddle multiple divisions in the transportation industry. Pressure Pro’s tire-pressure monitoring system works on “every vehicle that has tires,” states Duane Sprague, CEO, who adds that the waste industry is an important market for them because “refuse trucks go to the dumps and hunt nails.”

Prior to TPM, the driver was responsible for daily tire inspections-“but the novelty wears off quickly,” Sprague notes. “Now, all they have to do is push a button in the cab.”

The TPM system augments telematics systems already in the truck. A sensor weighing 0.62 ounces replaces the valve stem cap mounted on the tire. Sending wireless transmissions every five minutes, it monitors around the clock and can last as long as seven years.

Alerts can be forwarded and customized. “You can get a lot of detail or just an alert,” Sprague says. You can also choose to monitor anything you want, such as heat, tire pressure, oil pressure, fuel, door openings, location, or brake heat.

Because heat can create problems, the system is adjustable to reflect heat conditions or a dragging brake shoe. “Bearings can cause heat too,” Sprague says. “Heat is the end destroyer-it disintegrates tires. Above 224 degrees, rubber disintegrates.” The system monitors heat via pressure and reports when pressures begin to fall.

“A tire can be saved with a timely alert,” Sprague says. The system saves tires and money. “Most haulers go through an average of three tires per month. Tires are costly, and so is downtime for maintenance.”

He says the system can be amortized with one prevented tire calamity. “Exploding tires create a lot of energy. Flying rubber is dangerous to pedestrians and can wipe out air brake lines, hydraulic lines…do body damage…”

Incorporating TPM means no time waiting on repairs and no angry customers. Tire life is extended, downtime reduced. “Tread wears evenly if the tire is happy,” Sprague concludes. And if they’re happy, “tires last longer.”

Putting the Brakes on Electronic Monitoring

Not all monitoring systems are electronic. BrakeSentry offers a manual indicator for the condition of brake adjustment for air brakes. “It provides a visual indication,” sums up Daniel Judson, technical director. “It eliminates having to measure…which few do.”

He says brake out-of-adjustment is the No. 1 safety defect. “They’re always an issue.”

One in 10 vehicles has brake violations, and brake adjustment defects account for nearly 30% of all truck crashes, which is why brake out-of-adjustment violations carry a severity rating of 4 on the CSA Behavioral Analysis and Safety Improvement Categories (BASIC) safety scoring system, making it one of the top equipment violations affecting a fleet’s safety score.

Undetected defects increase risk and contribute to costly repairs. According to the Federal Motor Carrier Safety Administration, the average cost to a fleet of an injury accident is $245,000, and the average cost of a fatality is $3.4 million.

Since the chamber’s push rod stroke is physically limited, it’s critical for stroke to be maintained within the narrow margin of safe operating limits. According to BrakeSentry, “a mere fraction of an inch of excess stroke can mean the difference between safe and unsafe braking.” Unless adjustment is within those limits, it doesn’t matter how hard the driver presses on the brake pedal.

Brake stroke cannot be visually inspected and checking brakes by “feel” is unreliable. According to the North American Brake Safety Conference, the use of visual brake stroke indicators is “the single most meaningful change that can be made to improve brake compliance.”

Judson explains that there is a legal requirement with automatic brake adjusters and that daily inspections are mandated. “Some brake chamber manufacturers meet the law with colored tape and paint, but they become useless quickly.” BrakeSentry helps keep haulers in compliance.

BrakeSentry offers a fast, safe “applied stroke” inspection that doesn’t require crawling under the vehicle to mark and measure pushrod stroke at each airbrake chamber. “It reduces maintenance time,” Judson says. “It usually takes 20 minutes to check brake stroke; with ours, it’s less than two.”

The brake stroke indicators provide a quick return on investment. BrakeSentry cites the New York City Department of Sanitation and Waste Industries USA Inc. on cost savings and other benefits. Their time/labor/cost analyses examined 50 tandem axle trucks, each of which underwent a monthly PM inspection. The average time to inspect brake stroke adjustment using the industry-prescribed “applied stroke” method was 25 minutes. Over the period of a year, that added up to 249.6 hours, at a cost of $9,984. With BrakeSentry, they were able to reduce the time to 20.4 hours and just $816 per year. That captured savings of 229.2 hours and $9,168 annually. Additional savings could be assumed due to the reduced need to perform major brake work.

The universal design fits on any vehicle equipped with airbrake chambers that have and exposed five-eighth-inch-diameter pushrod. Quickly installed without special tools, they are constructed of a flexible polyeurathane that can’t be damaged, requires no maintenance because it has no parts to wear out and is not subject to breakage from vibration. Used in the frigid temperatures in Alaska, they also stand up to conditions at landfills. In fact, he points out, they were designed with that in mind. “They’re almost bulletproof and should last the lifetime of the vehicle,” Judson claims.

Lifetime Guarantee

When an item is designed to last the lifetime of the vehicle, there’s no need to monitor it. “With robust lighting, the need isn’t there for a detection system,” reiterates Brad Van Riper, senior vice president and chief technology officer for Truck-Lite Co.

Prior to 1995, he says, lighting was considered consumable. But now, the product is part of the system for the life of the truck. “It’s robust-and if it doesn’t fail, you don’t need a detection system. “˜Fit and forget,’ No maintenance, less money in labor and replacement…and monitoring.”

Van Riper traces the history of his company as it followed the development of lighting. “Historically, we were a manufacturer of lighting products surrounding incandescent bulb technology-essentially, an electric company that integrated bulbs with sockets.”

Over time, he continues, fleets asked for help because they saw an average of one light per vehicle per month fail. In the early 1990s, bulb outage detection technology was matched by improvement in light-emitting diodes. “We essentially changed from an electric business to an electronic business,” Van Riper says.

After the launch of LEDs, it was discovered that properly equipped LED would not fail from shock or vibration. “They last 50,000 to 100,000 hours,” Van Riper estimates, adding that several fleets reported no failures in a one-year period. “The need for a detection system goes away when the technology is this robust.”

Because most US fleets are unionized, there is a distinction between what the operators and the technicians do. “The driver doesn’t replace lights,” Van Riper summarizes. But in Europe, the driver carries replacement bulbs, which is sparking debate about a mandatory move to get detection systems. They currently use 24-V bulbs that are less resistant to vibration, but a “simple move to LEDS would alleviate the need for bulb outage detection system and save them money,” Van Riper says

Penetration of LED technology is increasing continually as more are adopting it. “Since 1993, penetration (fleet adoption) has been in the mid-60% range,” Van Riper estimates. “All new products are LED. LED is richer; the color is truer.”

He believes it will be the dominant technology in the future, in part because the costs are being driven downward as the electronics industry continues to improve the technology. Although cost is fleet-dependent, he estimates payback in under one year.

However, he cautions, when improvement occurs in one area, a new downside appears elsewhere. “There is some resistance to installing connectors with equal robustness; that is the new weak link.”

Connectors were developed in the 1950s and 1960s, Van Riper explains. Open to the environment, they are subject to corrosion. New connectors are sealed to prevent splash and spray. As he says, they are “more robust.”

Chained to the Job

“Customer feedback on monitoring is that reports are nice, but someone has to look at them,” states Pat Freyer, president of Onspot Automatic Tire Chains. “Few monitor [the use of automatic tire chains]. It’s a matter of time allocation. Are the reports helpful? Yes, but someone must interpret them and take action. They aren’t interested in when a driver used Onspot. They know why chains and tires are torn up: Drivers are using them on dry roads at high speed.”

Because the shift-on-the-fly switch guard is a two-step process, Freyer says the automatic tire chains are rarely turned on by accident. With the chains on, vehicles are restricted to a maximum speed of 35 mph, but if the chains are needed, he says, those speeds are unlikely to be exceeded due to road conditions.

The system is permanently mounted to the rear suspension as a factory option or an aftermarket add-on through one of 1,400 dealers nationwide. It provides the traction of a single set of conventional snow chains at the flip of a switch, without having to stop the vehicle. Six lengths of chain spaced at 60-degree intervals on the chainwheel ensure that there are always two chains between the tire and road surface, whether the vehicle is accelerating, braking, or in a%2