If the steel body and componentry is the “skeleton” of the collection truck, then the hydraulics are the heartbeat of the mechanism that keeps it going, says Skip Berg, national sales manager, director of business development for automation, Labrie Enviroquip, which manufactures front and rear loaders.

In trash collection, the hydraulics provide trucks with the ability to lift large cans and heavy dumpsters, empty them into the truck, and compress the trash until the truck reaches its capacity. The hydraulics must perform with few breaks when on a route, at a range of engine and vehicle speeds, and in a variety of temperatures. Because operators are usually in a hurry to complete their routes, the hydraulics must be reliable and the controls simple.

Standard Equipment and Improvements

Hydraulics are the most maintenance-centric parts, Berg claims. That’s due to their exposure to excess heat, ambient temperature, contamination, leaks, and varying viscosity of oil. Labrie offers several innovative engineering solutions, some of which they pioneered.

“All garbage is local” is Berg’s mantra. What gets set out, where, and the weather varies from region to region. In cold weather operation, the oil gets thick if it’s not the right weight. Therefore, Labrie offers three weights of hydraulic oil.

Pressurized hydraulics in the tank draw air from the air brake system, creating head pressure, Berg explains. “If it sucks in air or oil with air bubbles, it results in a jerky motion and heat builds up, making it inefficient.” Air pressure on top of the tank avoids cavitation, but he says it’s not possible to mount the system high enough to occur naturally.

How oil is filtered can result in restrictions, which also cause heat. “You want the finest level of filtration you can get without restriction,” insists Berg. A pressure-side filter catches fine particles. Catching them is important because if the pump starts to degrade, small particles of metal can get pumped through the system, causing wear.

Labrie’s regenerative system returns the oil to speed up the cycle rather than just circulating it. A regeneration circuit can double the extension speed of a single-rod cylinder without using a larger pump. Thus, regeneration circuits save money because a smaller pump, motor, and tank can produce a faster cycle time. It also costs less to operate over the life of the machine.

Hybrid dual pumps feature one pump that runs the automated arm (with a small cylinder for speed and control) and one that runs the body and other functions at lower pressure. These proportional controls permit the operator to feather the arm.

“We can customize trucks to the application,” states Berg. “What you are doing and where are you doing it guide the design.” For example, an operator may prefer electric over hydraulic, not air over hydraulic, for cold weather applications.

Some improvements have been to make the bodies lighter. Labrie uses Hardox, a special steel that is heat-treated to infuse the entire thickness. “Southern California weight laws are strictly enforced and limiting,” acknowledges Berg. “We sell featherweight—lighter bodies—that won’t sell in Massachusetts because they won’t live there, where they have bigger loads to carry more weight and need stronger bodies.” That may be a contributing factor to a continuing trend of short or quick turnover of equipment from 8–10 years to 3–4 years, although Berg believes the primary factor is the desire to lessen maintenance expenses, which includes hydraulics.

A Changing Industry

Lifters have changed very little in the last 20 years, states James Rimsa, engineering manager for Perkins Manufacturing. He believes it would take “a true revolution in garbage collection service…before the back of the truck gets much of a makeover.”

While the demands of each application dictate the type of lifter required, Perkins’ D6220 Tipper-bar TuckAway and D6500 Cylinder lifters are designed to be a fleet’s “daily drivers,” providing the strength and durability demanded by the customer.

Not only does the customer expect more out of the equipment, but the industry “has really put operator safety and strain prevention as one of their top priorities,” explains Hubert Gutierrez, international sales. That’s why Perkins is focusing on automation, developing new products that perform without the operator having to leave the collection truck.

Perkins’ D6220 cart lifter

The Can

Keeping the operator in the cab is an important safety aspect of trash collection. The Curotto-Can does just that—and more, like keeping the operator’s eyes looking forward instead of behind the truck, allowing them to preview material before it’s dumped into the hopper and remove contamination if necessary. “You’ll never lose a cart,” predicts John Curotto, president, “because they won’t fall into the hopper.” Thus, the cost of cart damage or loss is eliminated.

The location of a short arm placed forward of the steer axle speeds up the procedure. Curotto says that the average cycle time (from wheel stop to start) is 10–12 seconds, but that’s reduced to 4–5 seconds with Curotto-Can. Using a front loader platform, the Curotto-Can Automated Carry Can has the fastest load time of any automated system on the market, Curotto says. He indicates that it delivers a 25–30% productivity advantage over automated side loaders and has the robust reliability of a front loader.

Not only is the design ergonomic, but it’s also economical. The shorter arm has smaller cylinders, which saves fuel. “The competitors use a long stroke,” says Curotto. “It burns more fuel.” The Curotto-Can uses less oil and, in turn, creates less heat. In addition, the shorter arm exerts less stress on the hydraulics, as opposed to a long arm. The low lift-over height and short arm create a different leverage point so that the truck doesn’t rock or swing during loading.

When productivity is higher, Curotto says, fewer trucks are needed. That saves money. Further contributing to productivity, the Curotto-Can’s hopper is four times larger than that of an automated side loader, so bulk items can be hand-loaded, eliminating the need for a separate truck to collect large items. “We can get eight 96-gallon carts in even if they’re full.”

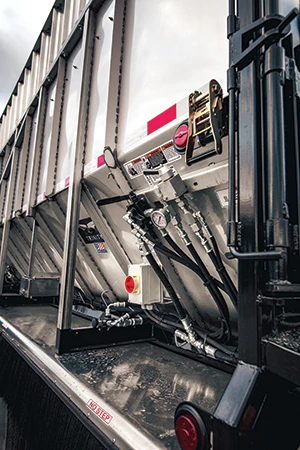

Hallco’s hydraulic system powers the live floor

Floor It

The “pure science” of hydraulics hasn’t changed for at least 40–45 years, claims Richard Moffitt, vice president of sales and marketing for Hallco Industries, Inc., a custom manufacturer of hydraulic reciprocity conveyors deployed in mobile and stationary applications. He says it still takes a certain number of gallons per minute to move product (speed) and a certain amount of horsepower to move the floor (force or pressure/tonnage).

However, there have been minor advancements, predominantly in safety, particularly in using a remote control to get the driver away from the back of the truck when it starts—in case they forgot to open the door, for example. This can be a cost-saver because, Moffitt explains, the cost of a manual door with a safety airlock is high.

There have also been advances in moving floors. Hallco designs live floor systems that are hydraulically powered. Comprised of a series of deck slats that move in sequence to load and unload completely and quickly, these systems fit a 30-foot to 53-foot trailer. “It all depends on what you’re hauling,” says Moffitt. “Trailers usually scale out before they cube out.” In other words, they typically hit the legal weight limit by carrying heavy products before they fill up space with lighter material.

The drive units and deck profiles have been designed to cater to customers’ needs for lightweight, heavy-duty, or leak-resistant uses. “Different systems have different weights, so we consult with customers on the best hydraulic package and floor system,” details Moffitt, adding that the Brute system is leak-proof.

At transfer stations, a compactor is often used to fill a trailer and push material level with the trailer. “They use the floor to load, but they need abrasion resistance,” points out Moffitt. The back quarter of the trailer receives 100% of every load. By adding quarter-inch aluminum steel/half-inch welded steel wear strips to combat abrasion, the back 8–10 feet of the trailer enjoys a longer life. If the trailer is in a pit, he notes, a front loader usually loads from the top, so they would need impact resistance due to dropping material onto it.

Drive units are the mechanisms that drive the floor slats. They are comprised of hydraulic cylinders with strokes of 3 inches, 8 inches, and 10 inches in upper- and front-mount styles that are compatible with perimeter-frame or center-frame containers carrying loads ranging from 15,000 to 90,000 pounds.

Hydraulic packages in which the module mounts under the trailer help protect against road salt and grime due to their internal seals and anodized manifolds, Moffitt says. Shields are put over the drive system of under-mount drives to help the system last longer. It also improves PMs. “You get more life out of the hydraulics when you protect them from acidic leachate, which is corrosive to all metals.”

When the drive unit is mounted on the nose of the trailer instead of underneath, it requires shorter connections and allows for easier maintenance. The front-mount Brute drive serves a different purpose, Moffitt indicates. This leak-proof system that contains liquids is well-suited for wet materials, organics, and leachate. The Brute’s front-mount design allows it to be matched to leak-proof deck systems. “It also appeals because of the ease of maintenance.” Crews can conduct PMs or do inspections and repairs with no garbage “juice” coming down on the mechanics.

With a reputation for reliability and toughness, the Brute is simple and offers several advantages. Its design keeps the hydraulic module up and away from road salts and grime—fighting road corrosion. It shifts the weight of the floor driving mechanisms to the tractor, allowing more payload. There are no parts or hoses under the trailer, and it provides easy front access for repair, quick removal, or replacement.

One of the drawbacks of the Brute is that you lose 5 tons of pushing capacity compared with under-mount designs. “It doesn’t have the same force,” confesses Moffitt. Particularly in winter, you need more force to move product, he says. “If the load sits overnight and freezes, you need more force to move it. It all depends on what and where are you hauling. In warm states—California through the Mason Dixon line—the I4000 drive is sufficient, with 35 tons of pushing capacity. But in the Midwest and Northeast, you need the I6000 with 45 tons. It’s a science.”

Not Trailing Behind

Hauling recycled products requires a rugged and versatile belt trailer, says Cameron Eisenman, president, Trinity Trailer, the manufacturer of the original self-unloading trailer. Recycled products are usually lightweight, so haulers need 90- to 110-cubic-yard capacity, although the size of the trailer ultimately depends on state requirements and is driven by local bridge laws.

Trailer options include multiple sidewall heights and multiple extension combinations to address specific height and weight requirements. “You want to maximize cubic yards and keep weight down,” explains Eisenman.

He says that trailers for Waste Management are designed for the maximum legal height and weight because they often carry cardboard—a high-volume, low-density material. But not all recyclables are lightweight, so the frame is designed for a strong, flexible trailer without the weight issue of an I-beam, Eisenman continues.

The big concern is reliability. Trinity trailers feature a segmented chain and flap—like a conveyor—in which the individual flaps overlap each other. “It holds up well, is low-maintenance, and eliminates stretching,” says Eisenman. Panel chain was a big development, he adds, because “a big pain point is chain stretch.”

The trailers routinely handle green waste, fly ash, auto fluff, construction debris, crushed glass, compost, household garbage, and tire shreds. Because some products, like fly ash, vary in temperature and abrasiveness, the belt trailer options from Trinity include multiple liner thickness and height choices in either UHMW or HMW plastics. They also offer heavier flaps and high-temperature liners, as well as a special fly ash tarp with ports that accommodate the pump loading of the product if the fly ash is light and dusty.

Hydraulics operate the door, which swings up with a knife gate to open the whole back end. “It’s a big component and drive assembly,” states Eisenman. Trinity developed a manifold system with all the components in one central area for easy maintenance and the ability to add other hydraulic accessories.

The trailers also feature the Eagletron remote control system so drivers can unload without stepping out of the tractor. It’s a safety issue, but it also makes for easier cleaning because components are protected from the elements. PTO-driven trailers come with a wet kit from the truck for cleanliness and changing the oil filter. In addition, Eisenman says that the self-unloading belt trailers won’t crack up like a shuffle floor. “We developed the EagleBridge trailer to increase the customer’s ability to move more product.”

The hydraulics on these trailers operate in similar fashion to other hydraulics: cold weather is a challenge. “For extreme cases in the Dakotas,” continues Eisenman, “we offer an auxiliary heating system to preheat the hydraulic fluid to help it run faster if there are cold start issues.”

Resources

www.bit.ly/2KXdAkR

Latest from Waste Today

- Vecoplan to present modular solutions at IFAT 2026

- Terex Ecotec appoints Bradley Equipment as Texas distributor

- My Green Michigan expands depackaging capacity

- Washington selects Circular Action Alliance as PRO

- Ten-8 Industrial opens new central Florida service center

- Triumvirate Environmental acquires Environmental Waste Minimization

- Official NYC Bin availability expands ahead of deadline

- US Food Waste Pact’s 2025 Impact Report shows decrease in food waste