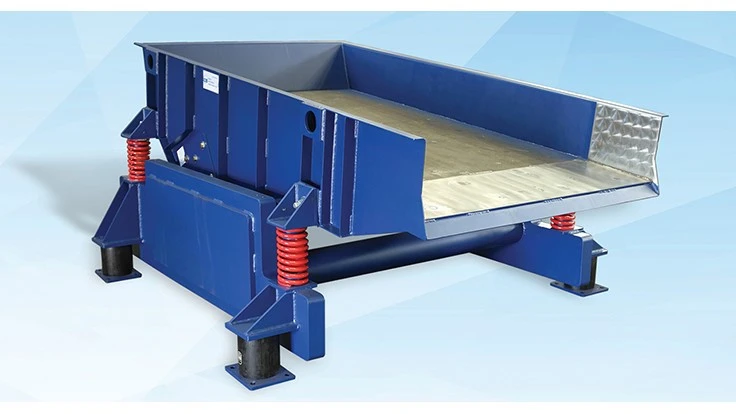

Brunswick, Ohio-based Best Process Solutions Inc. (BPS) says its feeders with vibrating troughs can be made to custom lengths, and that special trough designs are available.

The company says its vibratory feeders are designed to smoothly convey products and that the flow rate of material to be conveyed is adjustable and can be set to be variable or fixed.

BPS says it feeders are available in electric or air-operated models, and that the heavy-duty units are designed with above-, below- or side-mounted drives that can be arranged for base mounting or overhead suspension.

Several basic models are available including air-operated light duty, air-operated heavy duty, twin-motor vibrating pan and grizzly feeders, electromagnetic, twin motor and special application feeders. Options include the BPS Inertial Isolation System, which is designed to eliminate the transfer of vibratory energy to support structures and buildings.

BPS manufactures a line of custom-engineered, bulk-processing equipment and systems. The company says it serves several industry sectors, including aggregates and recycling.

Latest from Waste Today

- Vecoplan to present modular solutions at IFAT 2026

- Terex Ecotec appoints Bradley Equipment as Texas distributor

- My Green Michigan expands depackaging capacity

- Washington selects Circular Action Alliance as PRO

- Ten-8 Industrial opens new central Florida service center

- Triumvirate Environmental acquires Environmental Waste Minimization

- Official NYC Bin availability expands ahead of deadline

- US Food Waste Pact’s 2025 Impact Report shows decrease in food waste