Photo courtesy of Bioforcetech Corp.

Bioforcetech Corp., with U.S. headquarters in San Francisco, has announced its Sigma Pyrolysis system has achieved 99.98 percent per- and polyfluoroalkyl substances (PFAS) removal across all output streams, including biochar, discharge water and exhaust gases.

The results are consistent with previous findings from the Environmental Protection Agency published in 2022 and internal testing in 2020. Results were confirmed by engineering consulting firm Brown and Caldwell, of Walnut Creek, California, following testing at Silicon Valley Clean Water, of Redwood City, California, with the independent testing serving as the most exact and extensive testing conducted to date, according to Bioforcetech.

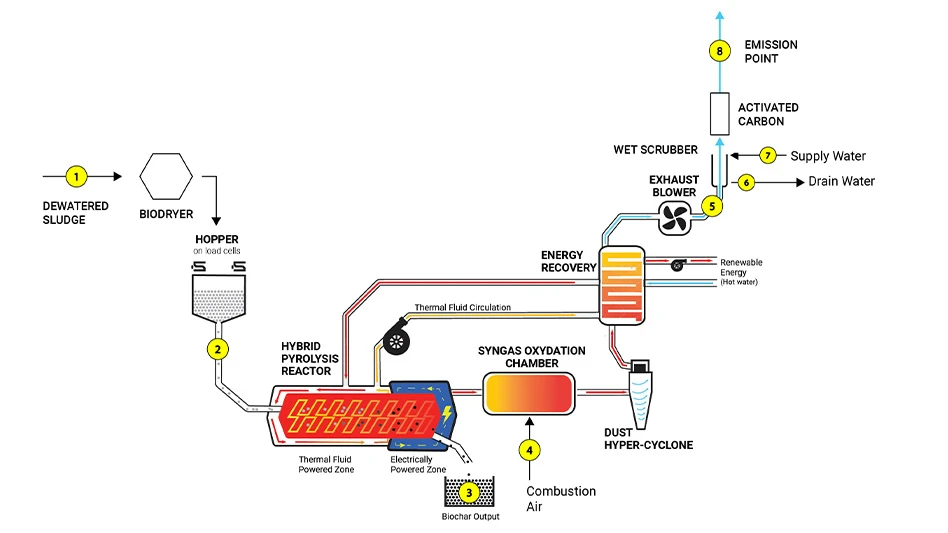

The study involved sampling at eight points throughout the Bioforcetech process, measuring PFAS concentrations in various outputs. Solids were analyzed using EPA 1633A, while exhaust gases were analyzed using the EPA’s OTM 45 method. Additional analyses were conducted in partnership with North Carolina State University.

The testing confirmed that of all PFAS compounds identified in the input material, 0.02 percent remained anywhere in the system (by molar weight).

The process point of highest removal was in the thermal oxidizer prior to exhaust scrubbing. According to Bioforcetech, this demonstrates that the company’s oxidizer design and specific parameters can successfully complete the bulk of the removal.

“We have spent countless hours designing our thermal oxidizer and following it with the specific scrubber that makes up much of the [Bioforcetech] Sigma Pyrolysis unit,” says Stefano Pessina, chief technology officer of Bioforcetech. “It’s great to see that the ‘3 Ts’ of time, temperature and turbulence that we have designed for are showing successful results in removing PFAS from the solid and gas stream as engineered.”

Testing also reconfirmed that all PFAS compounds identified in the input wet biosolid and dry biosolid material were 100 percent removed from the output OurCarbon—the company’s waste organics to clean fixed carbon material.

A peer reviewed article is currently in review and is expected between late 2025 and mid-2026.

“This milestone further drives the proof that pyrolysis of biosolids is a clear solution for the PFAS problem,” Bioforcetech CEO Dario Presezzi says. “The results from this testing give Bioforcetech even further confidence in our thermal process to alleviate wastewater plants of their ‘biosolids burden’ and produce a value-added output product.”

Latest from Waste Today

- RecycleNation helps people find nearby recycling facilities

- Hoffman Sanitation Services acquires Lake Texoma Trash Service

- Ecowaste Solutions acquires Howie’s Enterprises

- Fornnax appoints new sales partner in Germany

- Super Bowl LX will implement reusable cup program, AI recycling systems

- Fraser Valley Junk Solutions expands service availability

- Yale feature emphasizes pedestrian safety

- Monster Organics expands services to North Carolina