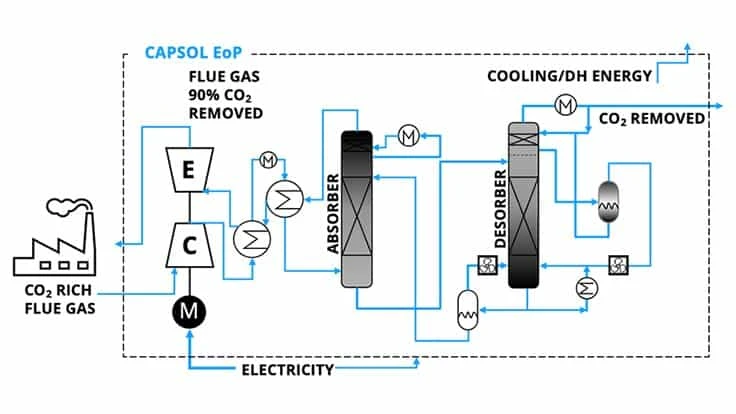

Graphic provided by Hitachi Zosen Inova.

Hitachi Zosen Inova (HZI), a Switzerland-based business unit of Japan’s Hitachi conglomerate, and Norway-based technology provider CO2 Capsol AS have signed a memorandum of understanding (MoU) to jointly implement a CO2 separation technology in energy-from-waste (EfW) applications.

The Capsol End of Pipe (EoP) technology uses hot potassium carbonate, which HZI says “does not pose a risk to people or the environment while being cost effective.” The EoP process connects to the end of the EfW process and is powered either by electricity generated by the plant or by a combination of electricity and steam from the EfW facility.

“The standalone system can be installed and commissioned without interrupting the plant’s operation,” states HZI. The CO2 separated can then be either liquefied, stored or used to produce methane in downstream processes, according to the technology firms.

Because of a patented heat recovery method, HZI calls the Capsol EoP technology “quite efficient with respect to operating costs. The energy requirement for separation is approximately 200 kilowatt hours (kWh) per metric ton, depending on the specific installation.”

“Capsol EoP is ideally suited to capturing CO2 from post combustion,” says Jan Kielland, CEO of CO2 Capsol. “In HZI, we have found a partner with whom we can establish this solution in EfW facilities.”

Comments Fabio Dinale, vice president business development at HZI, “This technology allows us to offer our customers a third process for separating CO2. It is robust, efficient and particularly suited to EfW plants that feature district heat extraction, since the process makes it possible to extract more total heat.”

HZI calls the agreement “another key milestone” in its “ambitious decarbonization plan.” Adds the firm, “It comes in addition to [our] existing amine scrubbing separation (Aker-type) and mineralization technologies for carbon capture (Carbonfree), storage and utilization (CCS/U). Each process has specific advantages and disadvantages depending on a plant’s location, connections and operating methods. HZI aims to be in a position to offer the best possible solution for every specific requirement in order to support decarbonization and implement circular economy landscapes globally.”

Latest from Waste Today

- Vermeer announces plan to build new facility in Des Moines metro area

- Buffalo Biodiesel shares updates on Part 360 application to DEC, Tonawanda facility progress

- Capstar Disposal expands roll off dumpster rental services

- Supreme Court strikes down IEEPA tariffs

- Casella details facility closures, expansion efforts

- Zero harm: Building a SIF prevention program for waste and recycling operations

- Casella posts a loss in Q4 2025

- McNeilus names Haaker Equipment first Dealer Partner of the Year