Industrial Magnetics Inc. (IMI), Boyne City, Michigan, has published a new tool on its website to help plant managers calculate potential revenue loss from their existing used beverage can (UBC) recovery lines.

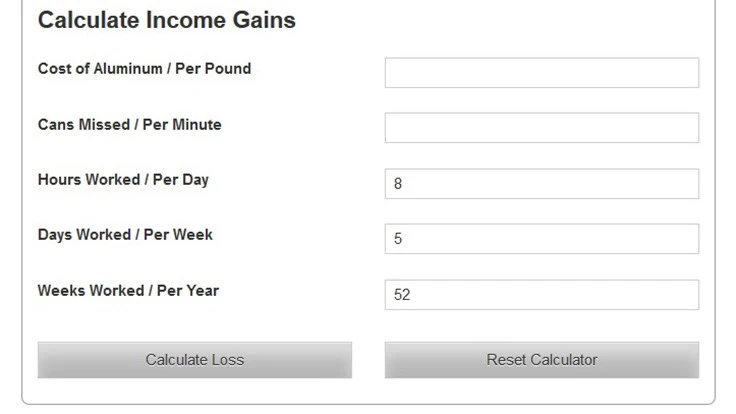

The tool calculates income gains after users input information related to cost of aluminum per pound, cans missed per minute, hours worked per day, days worked per week and weeks worked per year. It can be accessed by clicking here.

“Reclaiming aluminum cans typically involves the use of an eddy current magnetic separator, which repels the can as it passes through the magnetic field. In this way, the aluminum is ‘thrown’ and separated from the rest of the waste stream for recycling,” IMI explains in a press release.

The company continues, “As eddy current separators can vary in their magnetic field strength, overall design, and years in use, the tool aims to help users identify what the inefficiencies of their current equipment may be costing them. Taking into account factors such as number of cans missed in 60 seconds, the current price of aluminum and the number of hours the line runs, managers can better assess their current productivity and evaluate the payoff on the investment in new equipment.”

Latest from Waste Today

- Vecoplan to present modular solutions at IFAT 2026

- Terex Ecotec appoints Bradley Equipment as Texas distributor

- My Green Michigan expands depackaging capacity

- Washington selects Circular Action Alliance as PRO

- Ten-8 Industrial opens new central Florida service center

- Triumvirate Environmental acquires Environmental Waste Minimization

- Official NYC Bin availability expands ahead of deadline

- US Food Waste Pact’s 2025 Impact Report shows decrease in food waste