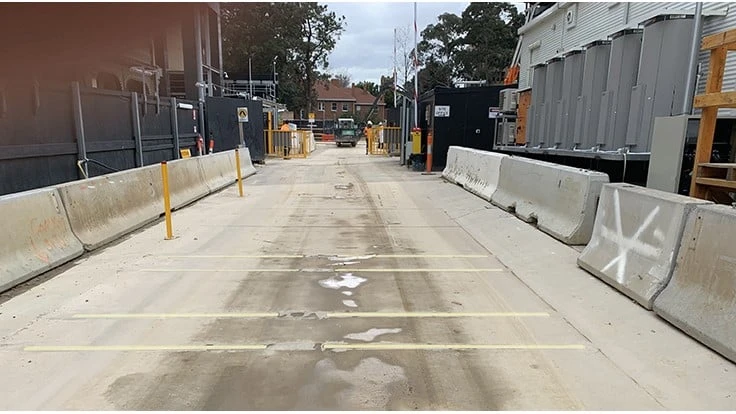

Photo courtesy of Intercomp.

Medina, Minnesota-based Intercomp says one of its Weigh-In-Motion (WIM) systems is providing an “efficient way to ensure vehicles leaving excavation worksites comply with commercial vehicle weight restrictions” for an infrastructure project in Australia.

Intercomp says Melbourne, Australia-based Fleet Plant Hire has been contracted by the local government to take part in a major infrastructure project for the city. Fleet Plant Hire provides heavy construction equipment and removal of excavated material from the project’s numerous worksites.

The city government included in the contract a requirement that makes all parties involved in hiring a commercial transportation company, including the vehicle owner and client, financially responsible for any transport law infractions (such as overweight trucks), according to Intercomp.

As a result, Fleet Plant Hire ordered several WIM systems, including Intercomp’s Strip Sensors, in mid-2018 to help ensure compliance.

“Strip Sensors are installed at a location where vehicles travel both directions, and there is not enough room for two access lanes,” says Garry Higgs of Fleet Plant Hire. “This road is used when relocating machinery, including excavators, around this worksite, something that could not be done with a traditional full-length truck scale, due to oversized cargo. We also need to keep the vehicles moving because, at times, 20 vehicles will travel the roadway in an hour.”

Intercomp describes Strip Sensors as one of several Intercomp WIM systems designed to help ensure vehicles leaving a worksite are weight-compliant while causing minimal disruption in a high-traffic location. “Nominal installation and maintenance requirements made Strip Sensors ideal for this [type of] location,” says Intercomp.

At the Australian worksite, digging restrictions did not allow for the two feet-by-six feet trench needed for the concrete foundation of a full-length truck scale. Strip Sensors require just a 3-inches-wide-by-3-inches deep channel cut into the pavement, says Intercomp.

Typical industrial applications need six- or eight-sensor configurations, spaced so they require a maximum of 17 feet. That compares with some 65 feet in length that might be needed for a traditional static truck scale, according to Intercomp. “This means Strip Sensors provide vehicle weighing data in one-third the space taken up by a traditional scale installation,” states the firm.

Latest from Waste Today

- Vecoplan to present modular solutions at IFAT 2026

- Terex Ecotec appoints Bradley Equipment as Texas distributor

- My Green Michigan expands depackaging capacity

- Washington selects Circular Action Alliance as PRO

- Ten-8 Industrial opens new central Florida service center

- Triumvirate Environmental acquires Environmental Waste Minimization

- Official NYC Bin availability expands ahead of deadline

- US Food Waste Pact’s 2025 Impact Report shows decrease in food waste