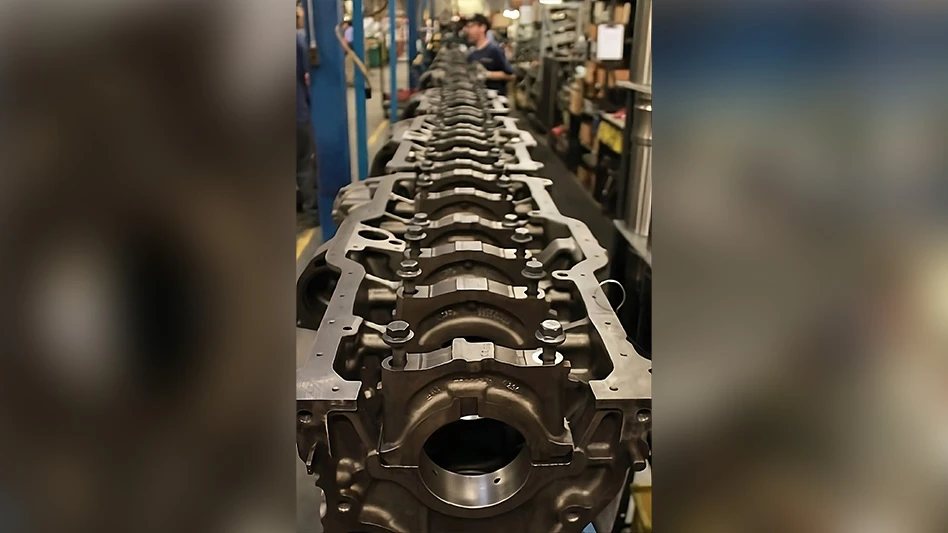

Image courtesy of Mack Trucks

Mack Trucks is commemorating 50 years of its Remack sustainable remanufacturing division in 2025.

In 1975, the company first founded the division in Lewisberry, Pennsylvania. Since then, Mack estimates it has remanufactured millions of components, turning used cores into “like-new” parts and preventing millions of pounds of materials from entering landfills.

“Remack exemplifies Mack’s dedication to both customer value and environmental stewardship,” says Richard Simons, senior vice president of aftermarket solutions, uptime and customer support at Mack Trucks. “This milestone not only marks years of engineering excellence, but decades of keeping valuable materials in productive use. By remanufacturing components to exacting Mack specifications, we’re providing our customers with cost-effective solutions while also making a meaningful contribution to sustainability by keeping valuable materials in productive use.”

Mack estimates its remanufacturing process uses up to 85 percent less material and 80 percent less energy when compared with new production initiatives.

“Every Remack component represents our commitment to quality and sustainability,” says Rick Cape, remanufactured technical product manager for Mack Trucks. “Our highly-trained technicians, with an average of over 22 years of experience, use advanced technologies like electromagnetic crack detection, precision CNC machining and dynamic testing to ensure each remanufactured part meets the same exacting standards as new parts. This meticulous process not only guarantees reliability for our customers but also maximizes the lifecycle of valuable materials.”

RELATED: Volvo Group commemorates 80 years in remanufacturing industry - Waste Today

Mack operates its Remack division out of two locales, including its Middletown Remanufacturing Center in Middletown, Pennsylvania, and Charlotte, North Carolina, facilities. Both facilities have achieved certified landfill-free status, maintain comprehensive recycling programs, and aim to support the generation of renewable energy for 100 percent of electricity demand, according to Mack.

Currently, the remanufacturing process includes more than 25 product lines, including coolant pumps, engines, Nox sensors and transmissions, among others, each of which undergoes inspection, cleaning, remanufacturing and testing via more than 1,800 precision gauges.

The Remak division has also expanded to remanufacture advanced components like Mack’s mDRIVE Automated Manual Transmissions, diesel exhaust fluid pumps and engine control units.

“What sets Remack apart is our philosophy of keeping matched component sets together throughout the remanufacturing process,” Cape says. “These parts have been machined together originally, and maintaining that synergy ensures optimal fit and performance while reducing waste. When replacement is necessary, we use 100 percent new pure Mack parts, including all bearings, seals and gaskets.”

For more information about Remack remanufactured parts, visit Mack’s website.

Latest from Waste Today

- The BDP compost system

- WM opens 2 new MRFs in Ontario

- Liberty Waste Solutions acquires AJ Disposal

- RecycleNation helps people find nearby recycling facilities

- Hoffman Sanitation Services acquires Lake Texoma Trash Service

- Ecowaste Solutions acquires Howie’s Enterprises

- Fornnax appoints new sales partner in Germany

- Super Bowl LX will implement reusable cup program, AI recycling systems