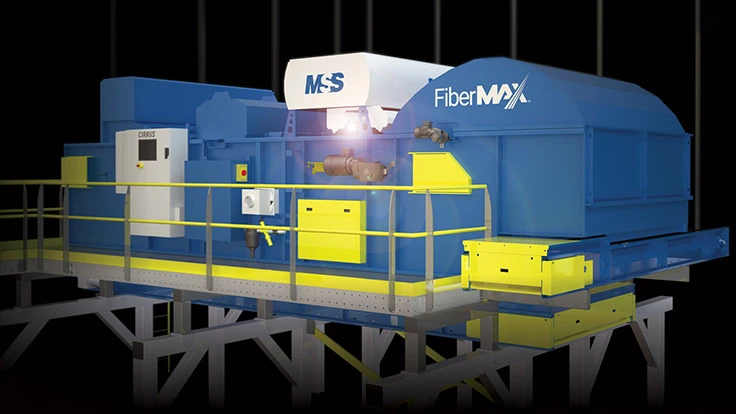

Nashville, Tennessee-based MSS Inc., the optical sorter division of the CP Group, San Diego, is introducing its next generation fiber sorting technology, the Cirrus FiberMax.

Based on the Cirrus sensor platform, the FiberMax provides increased sorting speeds, sensing capability and operating flexibility, MSS says.

The belt of the Cirrus FiberMax runs at twice the speed of conventional optical sorters, the manufacturer says, and a proprietary air-assist and material handling system keeps paper moving through the sensing zone in a laminar flow without turbulence. It sorts paper 40 times faster than manual sorting thanks to belt speeds of 1,000 feet per minute, MSS says.

The Cirrus FiberMax is equipped with an intuitive learning algorithm that adapts to changes in the material stream. An automated software assistant speeds up the programming of different or new types of contaminants and automates the fine-tuning of the sort recipe, all the while helping it to make distinctions the human eye can’t, the manufacturer says.

The Cirrus FiberMax is designed to generate a higher-purity paper grade for better marketability. In one recent installation, the Cirrus FiberMax decreased the level of prohibitives in a residential mixed paper stream from about 10 percent to less than 3 percent consistently, MSS says. Additionally, it reduced the sorter head count by 12.

The Cirrus FiberMax features a variety of upgrades, including an integrated vacuum suction system to remove ultra-light flexible packaging, such as film and bags, during the ejection process inside the eject hood, the manufacturer says. It can also be built to custom widths of up to 112 inches (2,800 millimeters).

MSS says the Cirrus FiberMax currently is running in commercial paper recycling operations (recovering mixed paper and sorted office paper) and residential fiber operations (removing prohibitives and outthrows from newspaper and mixed paper).

Greg Thibado, MSS vice president, says, “This is a very exciting next step for the Cirrus technology. The Cirrus FiberMax further improves on the already high NIR (near-infrared), color and metal scan rates and is running at faster belt speeds than ever before. These improvements future-proof the Cirrus FiberMax against any foreseeable changes in the material stream processed by MRFs and paper sorting facilities.”

CP Group—comprised of CP Manufacturing, Krause Manufacturing, MSS Inc., and Advanced MRF—provides award-winning recycling system design, manufacturing, retrofits, audits and consulting. CP Group provides turnkey solutions for mixed waste, residential recycling, commercial and industrial, construction and demolition and electronic scrap applications.

Latest from Waste Today

- Vermeer announces plan to build new facility in Des Moines metro area

- Buffalo Biodiesel shares updates on Part 360 application to DEC, Tonawanda facility progress

- Capstar Disposal expands roll off dumpster rental services

- Supreme Court strikes down IEEPA tariffs

- Casella details facility closures, expansion efforts

- Zero harm: Building a SIF prevention program for waste and recycling operations

- Casella posts a loss in Q4 2025

- McNeilus names Haaker Equipment first Dealer Partner of the Year