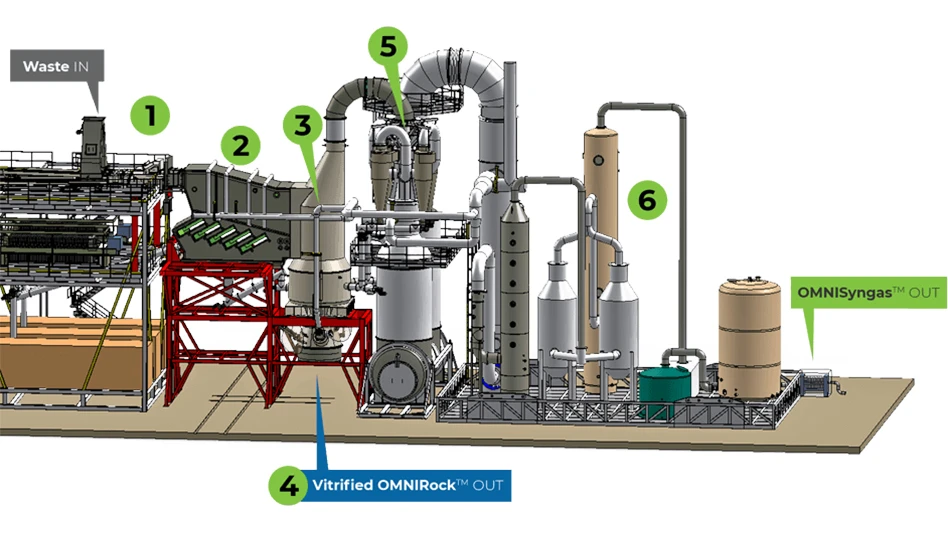

Image courtesy of OMNI Conversion Technologies Inc.

Ottawa, Ontario-based OMNI Conversion Technologies Inc. has been awarded the front-end engineering design (FEED) contract at the CST New Madrid LLC facility being planned by Minneapolis-based Circular SynTech LLC.

Circular SynTech says its technology is geared toward the production of renewable carbon-negative fuels, chemicals, infinitely recyclable plastics and other products from common waste streams.

For its planned CST New Madrid facility in New Madrid, Missouri, OMNI says it has now received orders for four of its Omni200 units, with the first one received this February.

The company says the Omni200 is a thermal chemical conversion system that has been proven at industrial scale and is a complete integrated system, delivered in large modules, rather than stick-built on-site.

Each module can receive and convert up to 200 metric tons per day (67,000 metric tons per year) of what OMNI says is a wide variety and mix of minimally prepared energetic wastes.

Post-conversion, the Omni200’s output consists of clean consistent syngas with a predictable heating value and composition, the firm says.

Circular SynTech, meanwhile, says the CST New Madrid facility will be the first of its kind to implement its proprietary OneStep catalysis for the production of waste-to-renewable fuels and chemicals.

The companies say the Omni200 technology will generate OmniSyngas at ratios required to react with Circular SynTech’s OneStep catalyst-producing reformates, which will then be distilled into renewable fuels or chemicals for the commercial market.

“This second FEED contract from CST New Madrid demonstrates a confidence in OMNI’s technology to deliver valuable and ultra-clean syngas while avoiding harmful methane emissions associated with landfilling waste,” says Jon Lundy, CEO of OMNI. “We are excited to support CST New Madrid’s rapid progress in producing renewable carbon negative chemicals in a unique and sustainable way while making a meaningful difference in the fight against climate change.”

“Circular SynTech is the perfect complement to the OMNI technology,” says Michael Harrelson, chief operations officer of CST New Madrid. “CST not only uses GHG-producing waste as its feedstock but also uses non-biogenic waste to create alternatives to fossil fuel-created distillates and chemicals. We couldn’t do this without OMNI.”

Latest from Waste Today

- Vermeer announces plan to build new facility in Des Moines metro area

- Buffalo Biodiesel shares updates on Part 360 application to DEC, Tonawanda facility progress

- Capstar Disposal expands roll off dumpster rental services

- Supreme Court strikes down IEEPA tariffs

- Casella details facility closures, expansion efforts

- Zero harm: Building a SIF prevention program for waste and recycling operations

- Casella posts a loss in Q4 2025

- McNeilus names Haaker Equipment first Dealer Partner of the Year