Photo courtesy of Power Knot LLC

Editors' note: This story has been updated from a previous version to reflect a Feb. 6 press release naming the catering and airport clients.

Power Knot LLC, headquartered in Fremont, California, has announced the successful installation of a fully integrated food waste processing facility at the Emirates Flight Catering (EKFC) facility at Dubai International Airport.

The catering facility is one of the world’s largest catering operations, Power Knot says, and serves hundreds of thousands of meals daily.

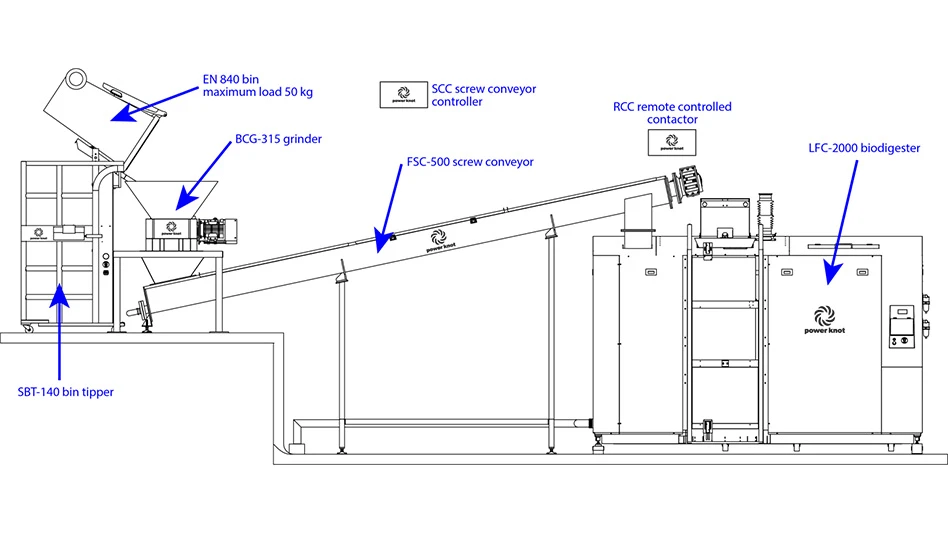

To address the challenge posed by organic waste generation, Power Knot deployed a system that includes its SBT-140 bin tipper, BCG-315 grinder, FSC-500 screw conveyor and an LFC-2000 biodigester.

RELATED: Power Knot releases BCG-315 organic waste grinder

At the center of the installation is the high-capacity LFC-2000 biodigester, capable of digesting thousands of kilograms (kg) of food waste per day. The SBT-140 bin tipper tips food waste into the BCG-315 grinder, which then chops up the organic material. The material is sent 5 meters (16.4 feet) through the FSC-500 to the digester.

Since its installation in December, EKFC typically deposits 80 bin loads a day, and the machine is digesting an average of 3,000 kg (6613.87 pounds) per day.

“This project highlights Power Knot’s ability to deliver integrated solutions for major food service operations,” Power Knot President Iain Milnes says. “With our technologies, catering facilities can process food waste more sustainably while at the same time reducing costs and improving operations.”

Latest from Waste Today

- Worn Again Technologies unveils Accelerator plant to advance polycotton recycling

- Nashville Waste Services launches new digital route system

- ACUA landfill expansion project unanimously approved

- Clean Energy announces multiple RNG deals with fleets nationwide

- Interchange 360 to operate alternative collection program under Washington’s RRA

- Waste Pro files brief supporting pause of FMCSA CDL eligibility rule

- New Way Trucks expands US network with Joe Johnson Equipment

- Tire Industry Project publishes end-of-life tire management guide