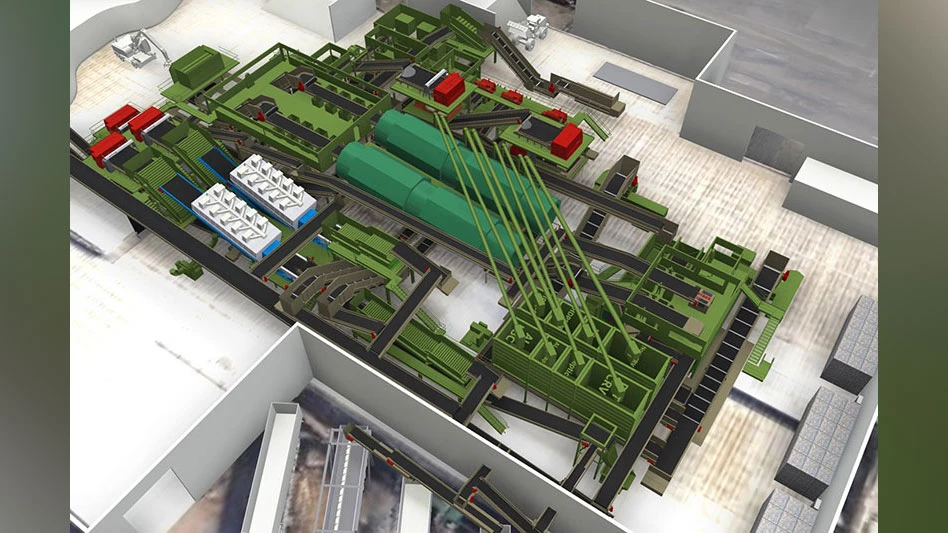

Image courtesy of BHS

Bulk Handling Systems (BHS), Eugene, Oregon, has been selected to receive a $34.5 million contract to design, manufacture and install the NextGen Integrated Processing System at the Sunnyvale Materials Recovery and Transfer (SMaRT) Station to process material collected from Sunnyvale and Mountain View, California.

The NextGen System replaces existing equipment at the site. The NexGen System is capable of handling 100 tons per hour of municipal solid waste (MSW) and 20 tons per hour of source-separated recyclables.

The upgrade is designed to meet the NextGen Project’s goals:

- improving operational efficiency through a single integrated system for both MSW and source-separated recyclables;

- supporting Sunnyvale’s long-term sustainability goals;

- increasing diversion rates while enhancing the purity and quality of recovered materials; and

- recovering and diverting more than 75 percent of inbound MSW organic material for composting, significantly reducing greenhouse gas emissions.

The system’s key technologies and features include:

- Max-AI AIR, a sorting solution that combines artificial intelligence (AI) with high-speed air ejection to accurately separate recyclables to reduce reliance on manual sorting;

- SpydIR-HS, a high-resolution optical sorter using hyperspectral imaging to identify and separate a wide range of materials with exceptional precision;

- Total Intelligence Platform, or T.I.P., which provides real-time monitoring and analytics of material composition and system performance, enabling data-driven decision-making;

- BHS Debris Roll Screen and OCC Separator, patented screening technologies that separate materials based on size and shape, improving throughput and purity; and

- Nihot Windshifter and Single Drum Separator, which is a BHS patented process that sorts materials based on density into heavy and light fractions, enhancing overall recovery rates.

“The NextGen System sets a new standard for integrated waste processing in Sunnyvale, combining cutting-edge technology with proven design to maximize recovery and operational efficiency,” BHS CEO Steve Miller says.

Founded in 1976, BHS uses an integrated approach that combines proprietary technologies with in-house engineering and manufacturing to ensure seamless and efficient project execution. BHS companies include Amsterdam-based Nihot, Nashville, Tennessee-based NRT and San Jose, California-based Zero Waste Energy. BHS also developed Max-AI detection and sorting technology.

Latest from Waste Today

- WM reports revenue, earnings growth in Q4 and full-year 2025

- Reclamation Technologies USA acquired by investment fund

- Stadler equips Spanish MRF

- Amlon adds Mastermelt facility to its portfolio

- US Composting Council releases draft bank loan kit

- Vecoplan appoints CFO

- Recovered paper traders report lukewarm market

- Maverick Environmental Equipment opens Detroit area location