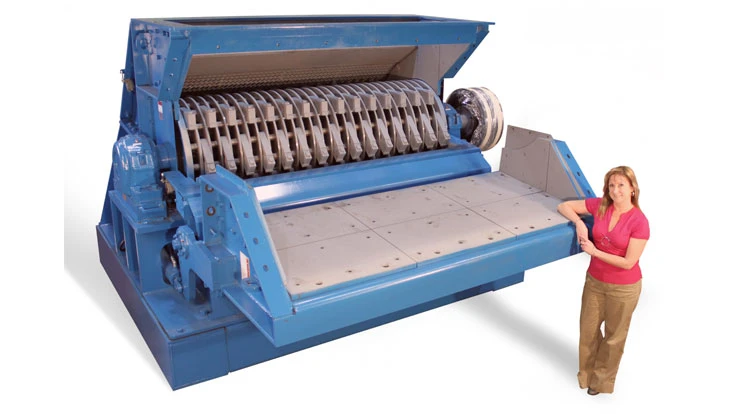

West Salem Machinery (WSM), Salem, Oregon, has introduced its Biomass Super Shredder, which the company says allows processing of a wide range of incoming green feedstock--pulp chips, micro-chips, in-woods chips, sawdust, shavings, and hogged wood--for improved drying and sizing for pellet manufacturing.

The WSM Biomass Super Shredder is specifically designed to deliver high-capacity and high-speed milling of green fiber at rates from 10 to 75 tons per hour. Available in rotor diameters of 42-inches, 48 inches, and 60 inches and rotor lengths from 36” to 88” long, these massive machines typically operate with 150 – 1000 HP. Features include modular and adjustable tooling with either rigid or swing hammers with replaceable inserts; large screen area with modular sizing screens to allow adjustment to product sizing; and heavy duty housing with interior wear liners and pivoting case access for long life and ease of maintenance. When combined with a WSM pre-screen, processing rates can reach up to 100+ tph. System integration into your wood handling system is no problem – WSM offers complete infeed and outfeed options to help you supplement your fiber supply with lower cost fiber from the WSM Biomass Super Shredder.

More information about WSM’s Biomass Super Shredder is available at www.westsalem.com.

Latest from Waste Today

- Vermeer announces plan to build new facility in Des Moines metro area

- Buffalo Biodiesel shares updates on Part 360 application to DEC, Tonawanda facility progress

- Capstar Disposal expands roll off dumpster rental services

- Supreme Court strikes down IEEPA tariffs

- Casella details facility closures, expansion efforts

- Zero harm: Building a SIF prevention program for waste and recycling operations

- Casella posts a loss in Q4 2025

- McNeilus names Haaker Equipment first Dealer Partner of the Year